At Revco Products, our manufacturing solutions will enable you to get your product to market quickly and efficiently. You’ll work one-on-one with an experienced project management team. This personalized approach helps us respond quickly to your project’s specific requirements as it progresses through the various phases of assembly and testing.

Scheduling Options

Book & Ship

We book your project to be manufactured and shipped one-time in its entirety.

Scheduled Build

We schedule your project to be manufactured and shipped at intervals and in quantities according to a specified schedule.

Kanban Programs

Utilizing our enhanced supply chain and personnel dedicated to your project, we will provide finished goods in a JIT (just in time) format. Kanban manufacturing requires superior communication between you and your account manager..

Manufacturing Options

Consignment

We assemble and ship your PCB assembly utilizing the PCB and electronic components that you furnish to us.

Turnkey

We procure the PCB and electronic components on your behalf. We assemble and ship your PCB assembly upon completion.

Box Build

Once we assemble your PCBA it is installed into a chassis or enclosure of your specification. The process may also include wire harnessing, electrical testing, and specialized packaging. Consignment or turnkey options are available for box build assemblies.

Pre-Production Services

Design for Manufacturability (DFM)

A DFM review provides the opportunity to identify any potential issues with the manufacturability of your design. This proactive process enables us to reduce cost by refining your design before production begins.

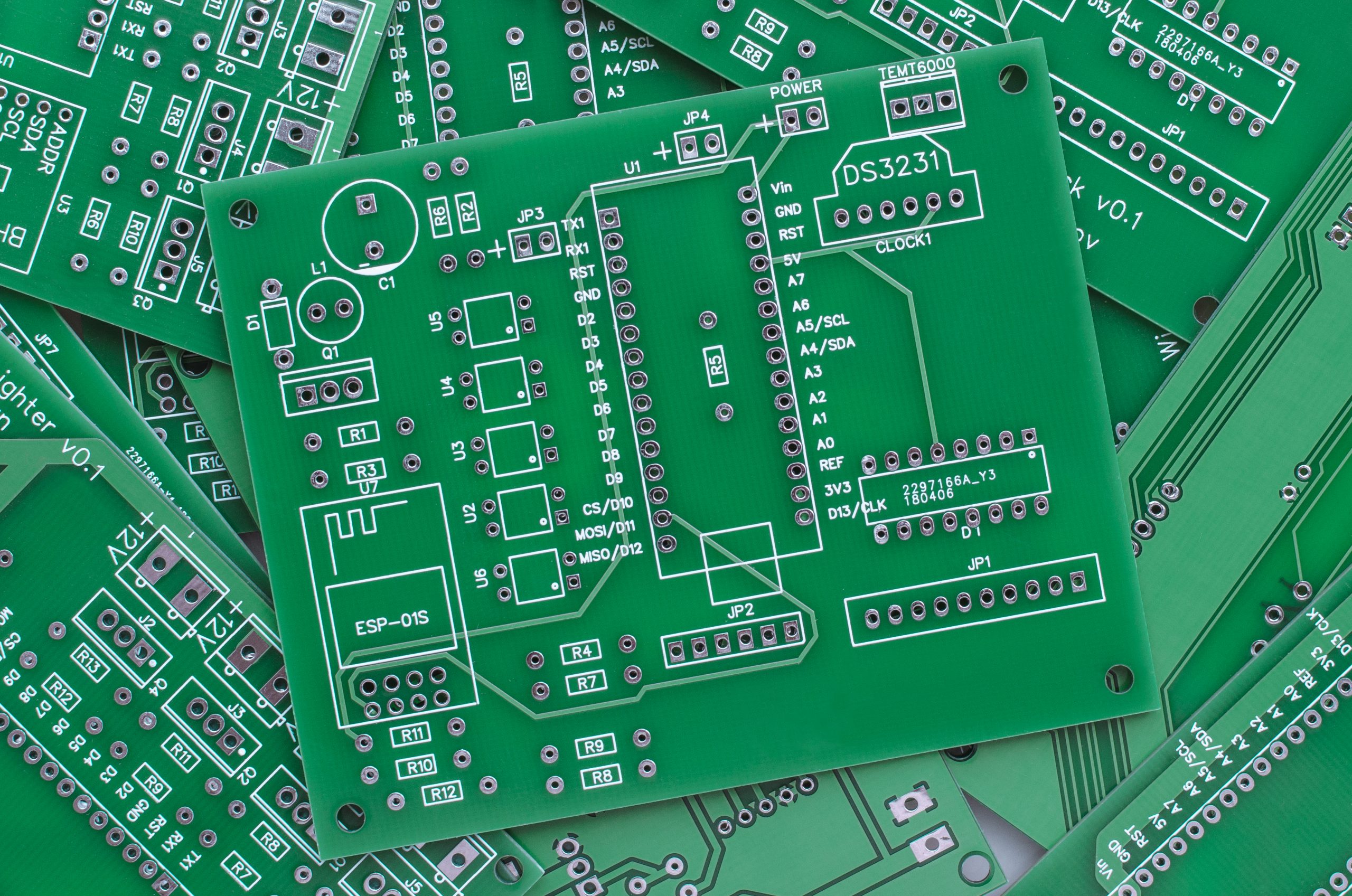

PCB Fabrication

Whether you need a few boards fast or many boards on a schedule, we have a trusted network of PCB layout and fabrication partners. Our domestic and offshore suppliers are capable of meeting any requirement, including rigid, flexible, and high-thermal demand circuit boards.

Supply Chain Management

We can source your parts through our network of trusted suppliers. It takes years to develop a strong supply chain. Leveraging our connections minimizes lead times, avoids delays and reduces costs.

Prototyping

We can help validate the manufacturability of your designs; helping you avoid costly errors and creating opportunities for improvement before volume manufacturing begins.

Production Services

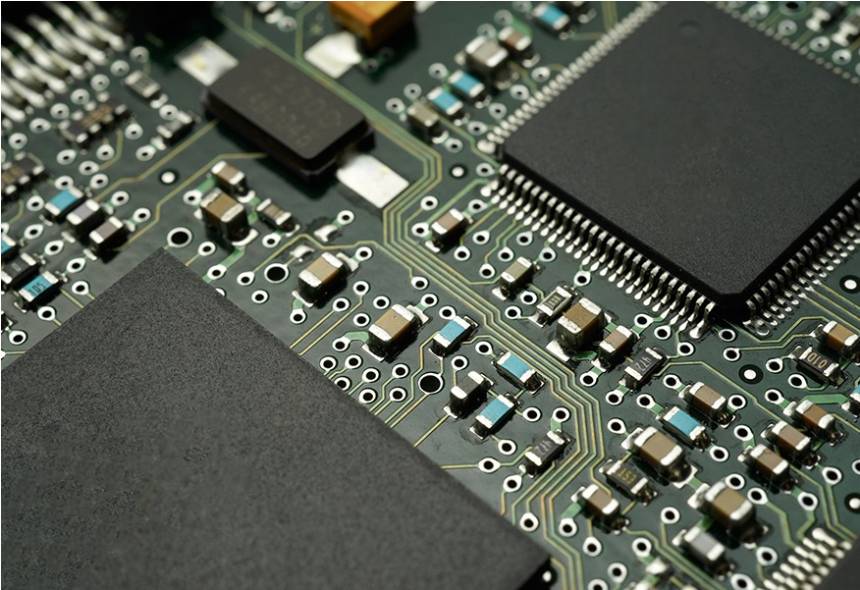

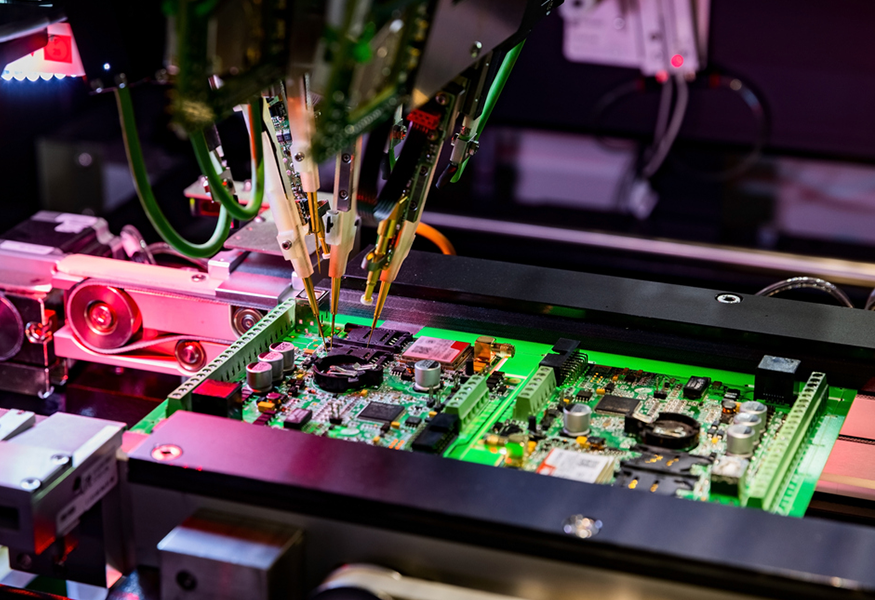

Surface Mount (SMT) Assembly

Revco is equipped with sophisticated SMT automation equipment to meet demands for miniaturized PCB assemblies. We can place ultra-fine pitch components including, but not limited to, flip chips, SOICs, QFPs, micro BGAs and 01005 package sizes.

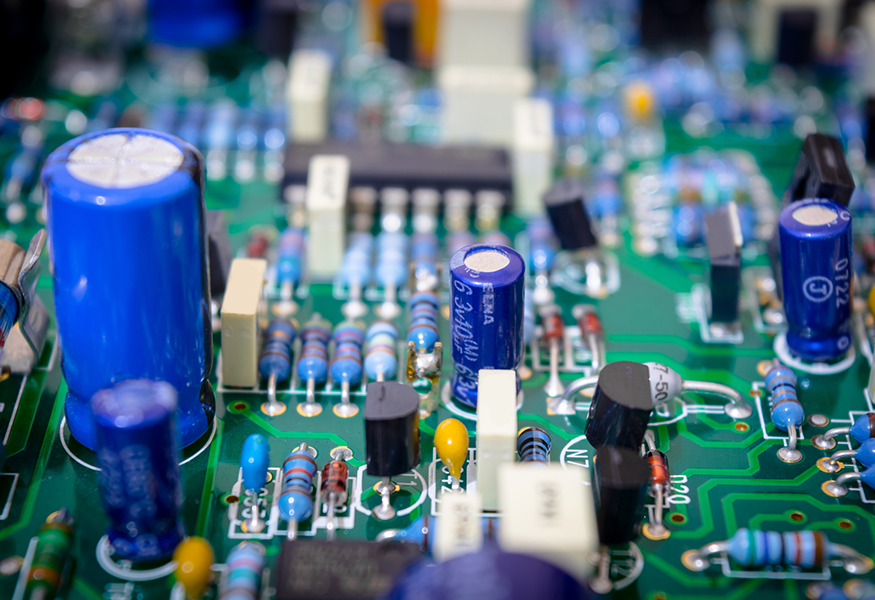

Thru-Hole (THT)

SMT assembly processes have replaced wave/hand soldering of thru-hole components in many cases. However, THT still offers mounting strength benefits that keep it relevant today and into the foreseeable future. Hand soldering is very much a skill that requires training and practice. At Revco Products, THT hand soldering is performed by our well-trained and competent soldering technicians.

Hybrid Technology (SMT & THT)

At Revco Products we can provide mixed technology PCB assemblies with both SMT and THT components. Our well-equipped facility and skilled technicians enable us to provide custom mixed technology assemblies based on your specific requirements.

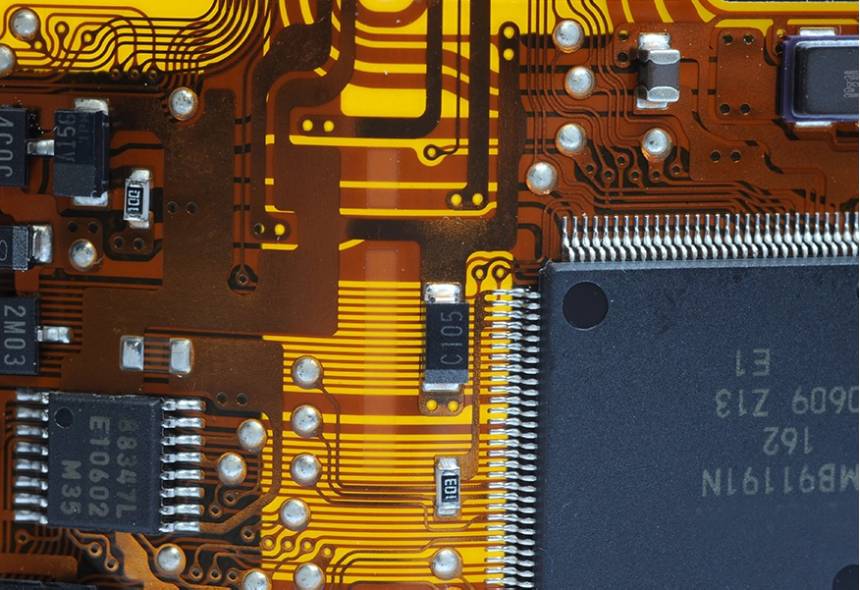

Rigid and/or Flexible PCBs

Utilizing the right technology can make a difference for your business. That’s why we offer both rigid and flexible PCB assembly services. Flexible circuits are thin, lightweight circuits that can bend and conform to small spaces and shapes. They enable slimmer product designs and are used in a wide range of industries from medical to aerospace.

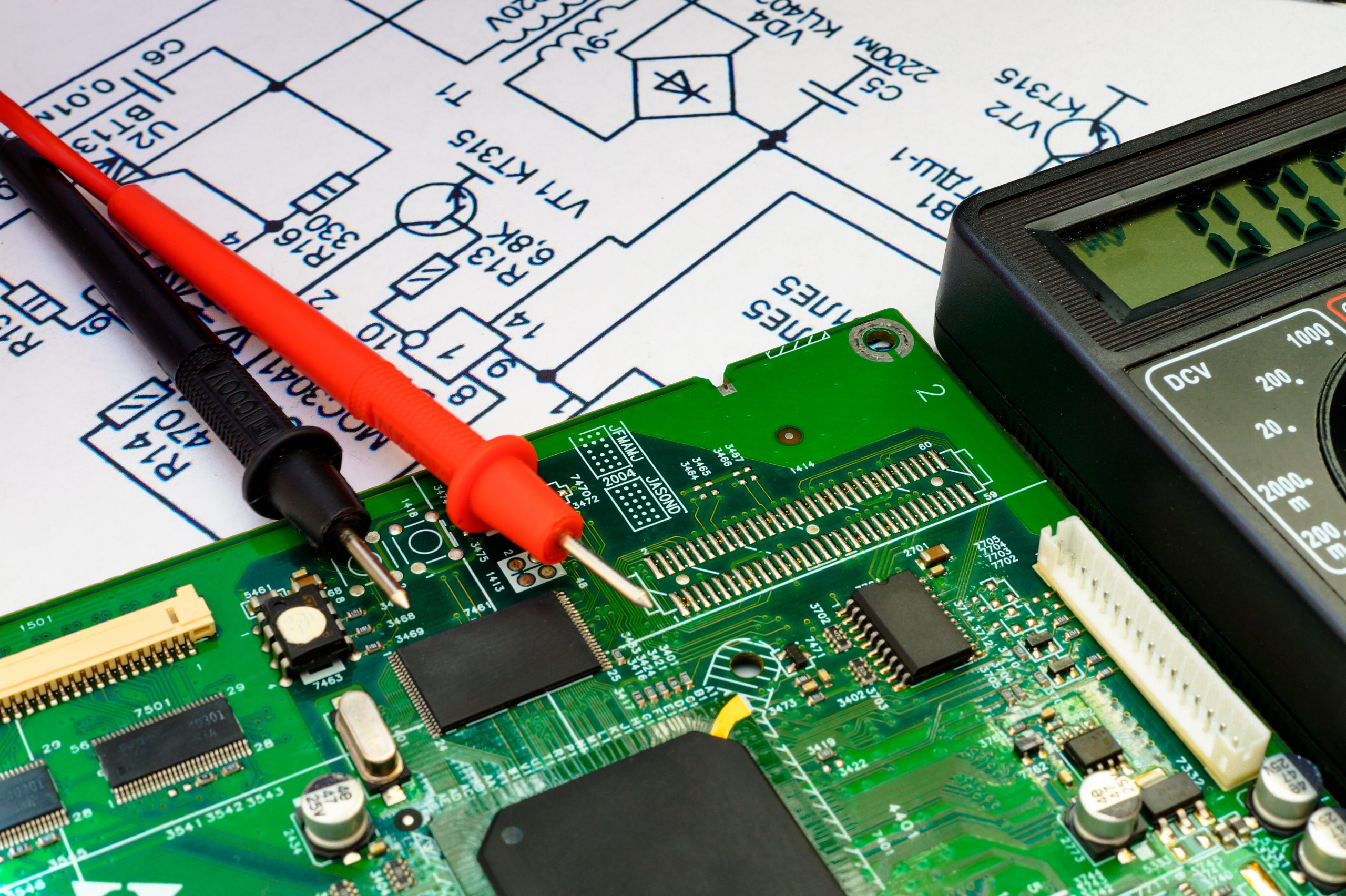

ICT & Go-No Go Testing

In addition to Automated Optical Inspections, Revco performs ICT, Go-No Go tests to ensure your product meets your specifications for full functionality and reliability.

Conformal Coating Services

Conformal coating is a protective non-conductive coating applied onto a PCB assembly. It protects the electronic assembly from moisture, contamination and mechanical vibrations in harsh environments, and enhances product reliability.

Leaded & Pb-Free Assembly

Lead free PCB assembly is rapidly becoming the standard for PCB manufacturing due to the RoHS directive adopted in the European Union in 2006. When required, Revco Products will ensure that your PCB assemblies are built to meet RoHS requirements. We also offer traditional lead-based solder for strong solder joint formation between difficult to solder alloys.